5-axis High-speed Laser Tube Cutting Machine

FEATURES

Fast dynamic response, high signal transmission efficiency, simplified circuit, good stability. Simple operation, 3D simulation real-time display of processing path.

High-quality cutting, worry-free quality. Acceleration 1.5gm/s, fast speed, high precision, stable light output, and precise plasticity of pipe cutting. After cutting, the incision is smooth and the burr rate is extremely low. It can be directly adapted to subsequent processes without additional grinding, ensuring processing quality and efficiency from the source.

Effectively improve processing accuracy and production efficiency, significantly reduce material loss and production costs, and the tailing is only 50MM.

ADVANTAGES

The servo clamp accurately pulls the pipe, with high reliability and stability, long-term trouble-free operation, and greatly reduces downtime. It supports high-speed cutting and special-shaped pipe processing, especially suitable for long pipes and multi-hole processing scenarios.

The five-axis linkage material rack builds a highly efficient automated production system. It can automatically identify the pipe for photoelectric scanning, accurately capture the narrow and wide sides of the pipe, and achieve truly automatic switching of pipe types without manual operation, which improves efficiency and promotes the precision and intelligence of the production process.

The five-axis fully automatic control system and the material rack system support the materials dynamically. The core components adopt the integrated design of aluminum-magnesium castings to reduce weight and extend the life of the equipment.

PARAMETER

|

item |

unit |

parameter |

|

Pipe diameter(maximum) |

mm |

Round tube: Φ13-Φ80;Square tube:13*13-60*60 Other tube types:≤80 |

|

Acceleration |

m/s² |

1.5G |

|

Feeding pipe length |

mm |

5000-7000 |

|

Manual feeding length |

mm |

Unlimited length |

|

Maximum speed |

|

1800°/s |

|

Repeat positioning accuracy |

mm |

±0.03mm |

|

Acceleration |

|

1.5G |

|

Chuck load |

KG |

80 |

|

Pulling method |

|

Servo |

|

Machine head Dimension(L×W×H) |

mm |

2350*1368*1930 |

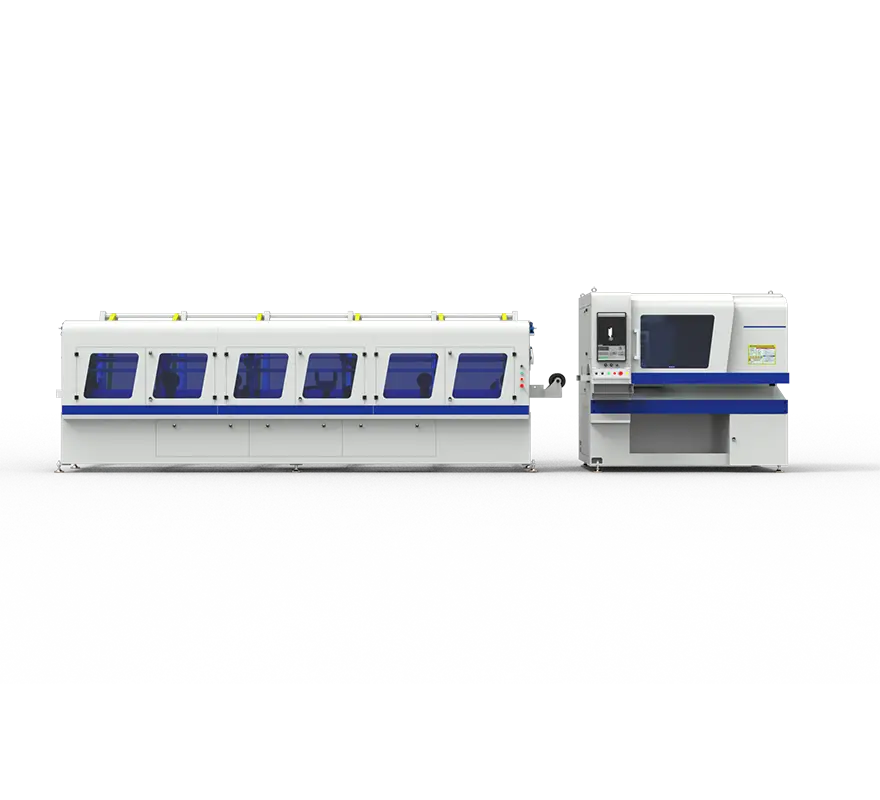

PRODUCT DISPLAY

|

LPC 80-A5-AF6000 Fully automatic loading Size: 8454*2087*1930mm Range of feeding tubes: 5000-7000mm |

|

|

LPC 80-A5-CF6000 Semi-automatic feeding Size: 8530*1631*1930mm Range of feeding tubes: 5000-7000mm |

|

|

LPC80-A5-DF6000 Manual feeding Size: 8080*1449*1930mm Range of feeding tubes: unlimited length |

Press Brake

Press Brake CNC Laser

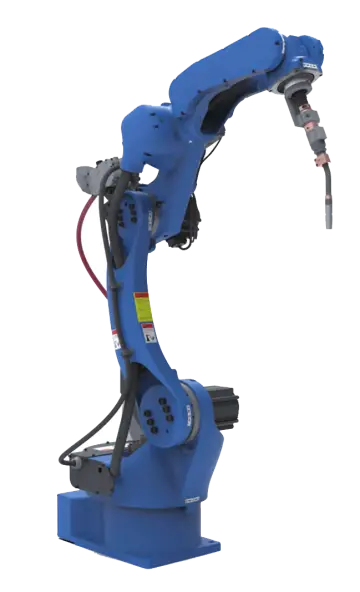

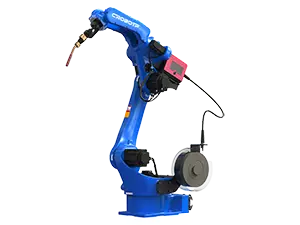

CNC Laser Industry Robot

Industry Robot Plate Rolling Machine

Plate Rolling Machine Tube Bending Machine

Tube Bending Machine Lathe and Machining Center

Lathe and Machining Center Machine Protection Products

Machine Protection Products