How to choose a suitable plate roling machine

Choosing a suitable plate Rolling Machine requires comprehensive consideration of the material and thickness of the plate to be rolled. The following are some common plate rolling machine types and their applicable situations:

1. Two-roller plate rolling machine: suitable for rolling thin plates with high strength of 6-10mm.

2. Symmetrical three-roller plate rolling machine: simple structure, wide application range, but no pre-bending function, the remaining straight edge after rolling is large, and it is necessary to purchase additional edge pressing equipment. It is suitable for plates of various thicknesses, but is more commonly used for rolling medium and thin plates.

3. Asymmetric three-roller plate rolling machine: has a single-side pre-bending function. If both sides of the plate need to be pre-bent, it needs to turn around. It is suitable for medium and thin plates.

4. Vertical downward adjustment three-roller plate rolling machine: can perform two-way pre-bending, suitable for medium and thin plates, which can greatly save the time of processing plates.

5. Inclined downward adjustment three-roller plate rolling machine: can also perform two-way pre-bending, rolling and pre-bending only require one feeding, and is also suitable for medium and thin plates.

6. Horizontal downward adjustment three-roller plate rolling machine: can be pre-bent in both directions, suitable for rolling plates of various thicknesses, especially for rolling medium and thick plates.

7. Arc downward adjustment three-roller plate rolling machine: can be pre-bent in both directions, suitable for rolling plates with a thickness of less than 80mm, which is relatively more conducive to the rolling of thick plates.

8. Universal three-roller plate rolling machine with upper roller: the upper roller can move both vertically and horizontally, can be pre-bent in both directions, and is suitable for plates with a thickness of 80-100mm.

9. Four-roller plate rolling machine: with higher precision, it can roll plates with a thickness of 80-100mm, and has higher rolling efficiency. It is divided into ordinary type and arc type. The upper roller of the ordinary type is fixed and rotated, the lower roller is lifted vertically, and the rollers on both sides are tilted and lifted; the movement mode of the upper and lower rollers of the arc type is the same as that of the ordinary type, and the rollers on both sides are lifted and lowered in an arc around a fixed point.

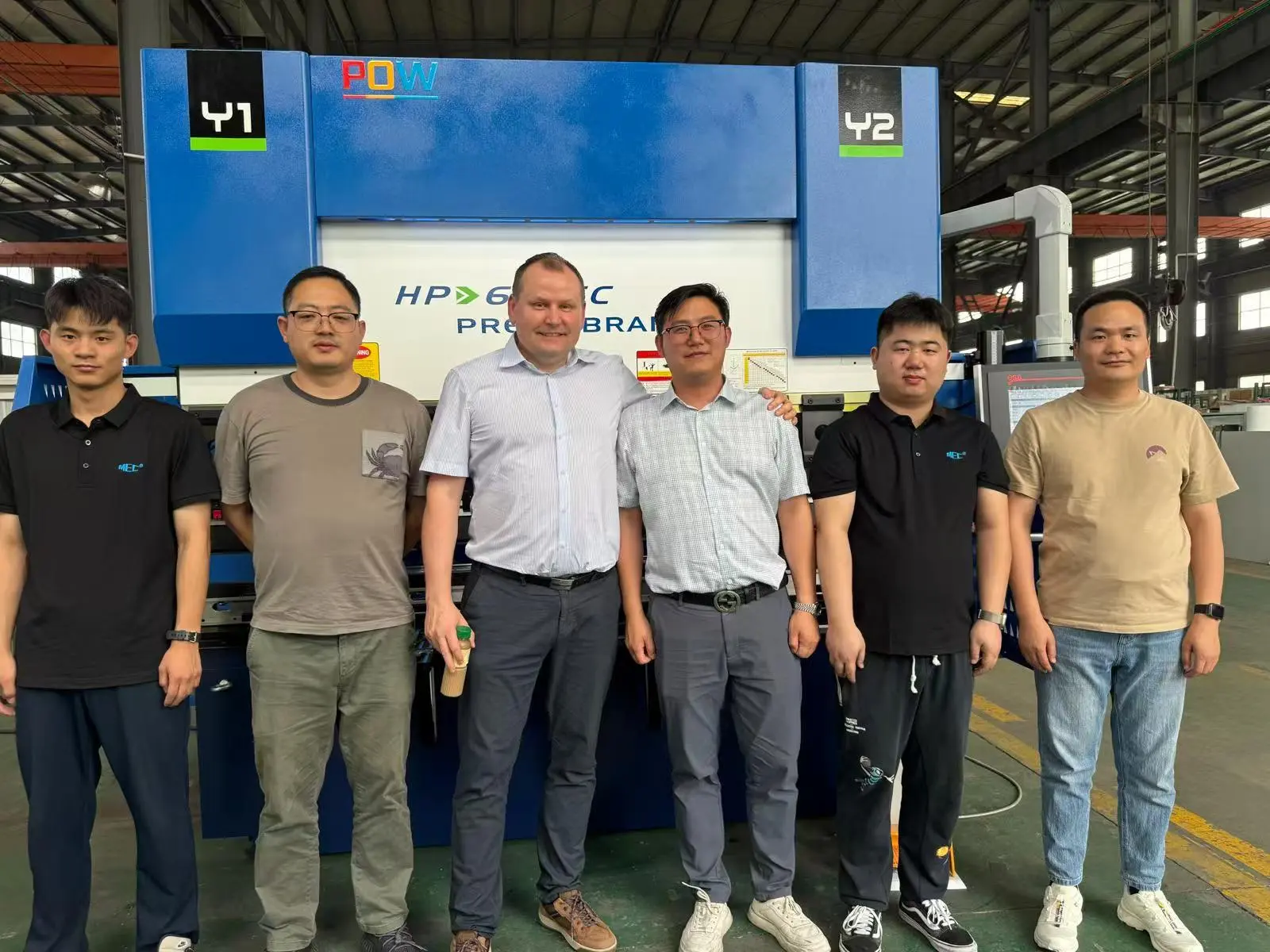

Press Brake

Press Brake CNC Laser

CNC Laser Industry Robot

Industry Robot Plate Rolling Machine

Plate Rolling Machine Tube Bending Machine

Tube Bending Machine Lathe and Machining Center

Lathe and Machining Center Machine Protection Products

Machine Protection Products