CNC fiber Laser cutting machines

In manufacturing and design, precision and efficiency are of the ulmost importance, then CNC Fiber Laser Cutting Machine came into being and completely changed the way materials are cut and formed. So what areas can laser cutting machines be used in? What are its advantages?

CNC Fiber Laser Cutting Machines are widely used in manufacture Billboard, Signs, Advertising, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc.

Fiber Laser Cutting machine is suitable for metal cutting like Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, If you equipped with the rotary axis, Metal Plate, all ok.

Compared with traditional cutting methods, the advantages of CNC fiber laser cutting machines mainly include fast cutting speed and high processing accuracy. The details include:

1. High precision, fast speed, narrow slit, small heat affected zone, smooth cutting surface;

2. Good processing flexibility, can also cut pipes and other special-shaped materials;

3. It can cut any hardness material without deformation;

Laser cutting speed: the cutting speed of laser cutting is more than 10 times that of traditional cutting methods, laser cutting quality is high: traditional cutting methods, the loss of materials is large, at the same time, from the cutting effect, it is not as good as laser cutting, usually requires secondary processing, and the accuracy is relatively lacking. The reason why laser cutting has very little damage to the material is mainly that it is a non-contact processing process, no secondary processing is required, and the accuracy is better than the traditional cutting method.

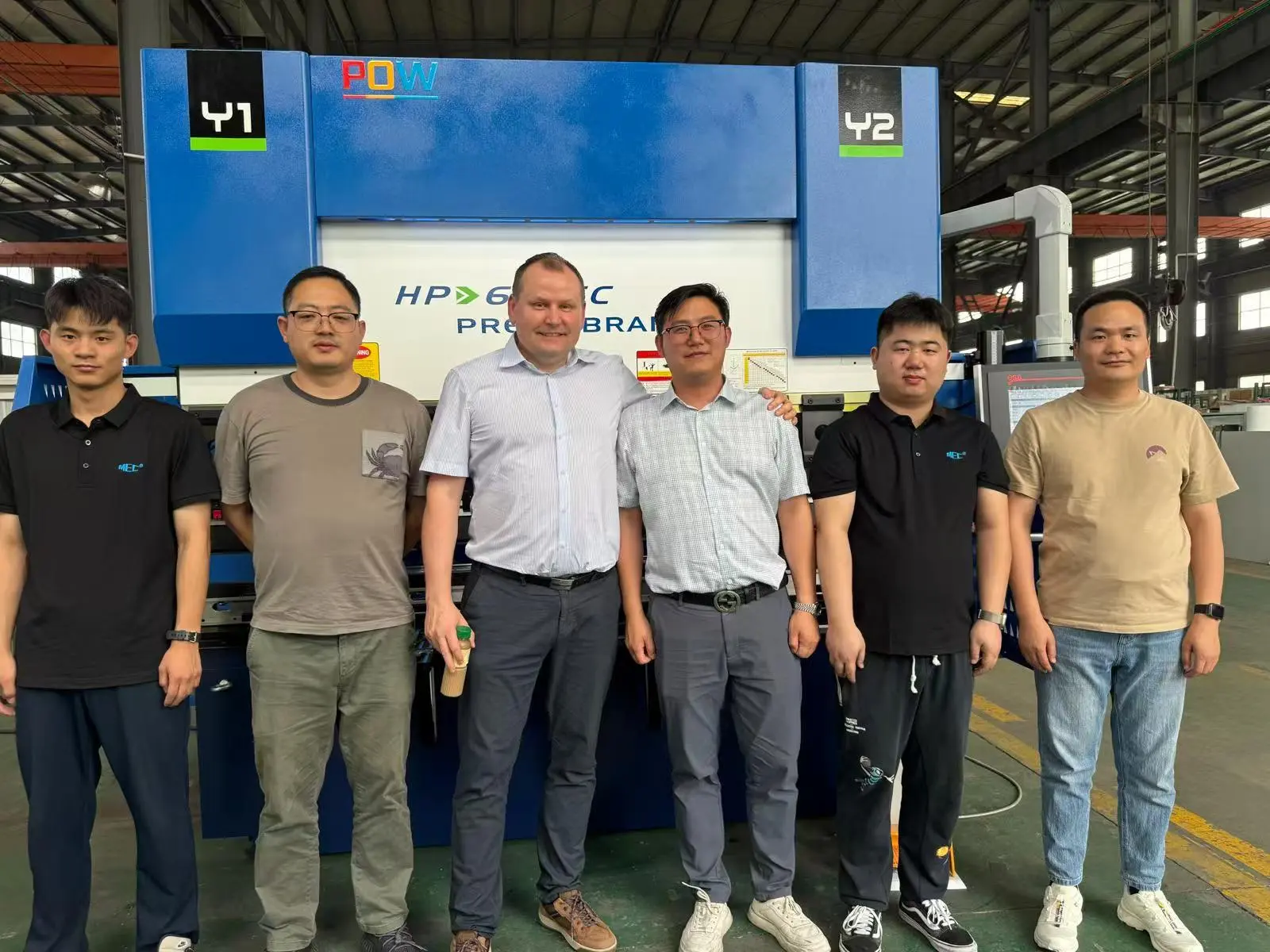

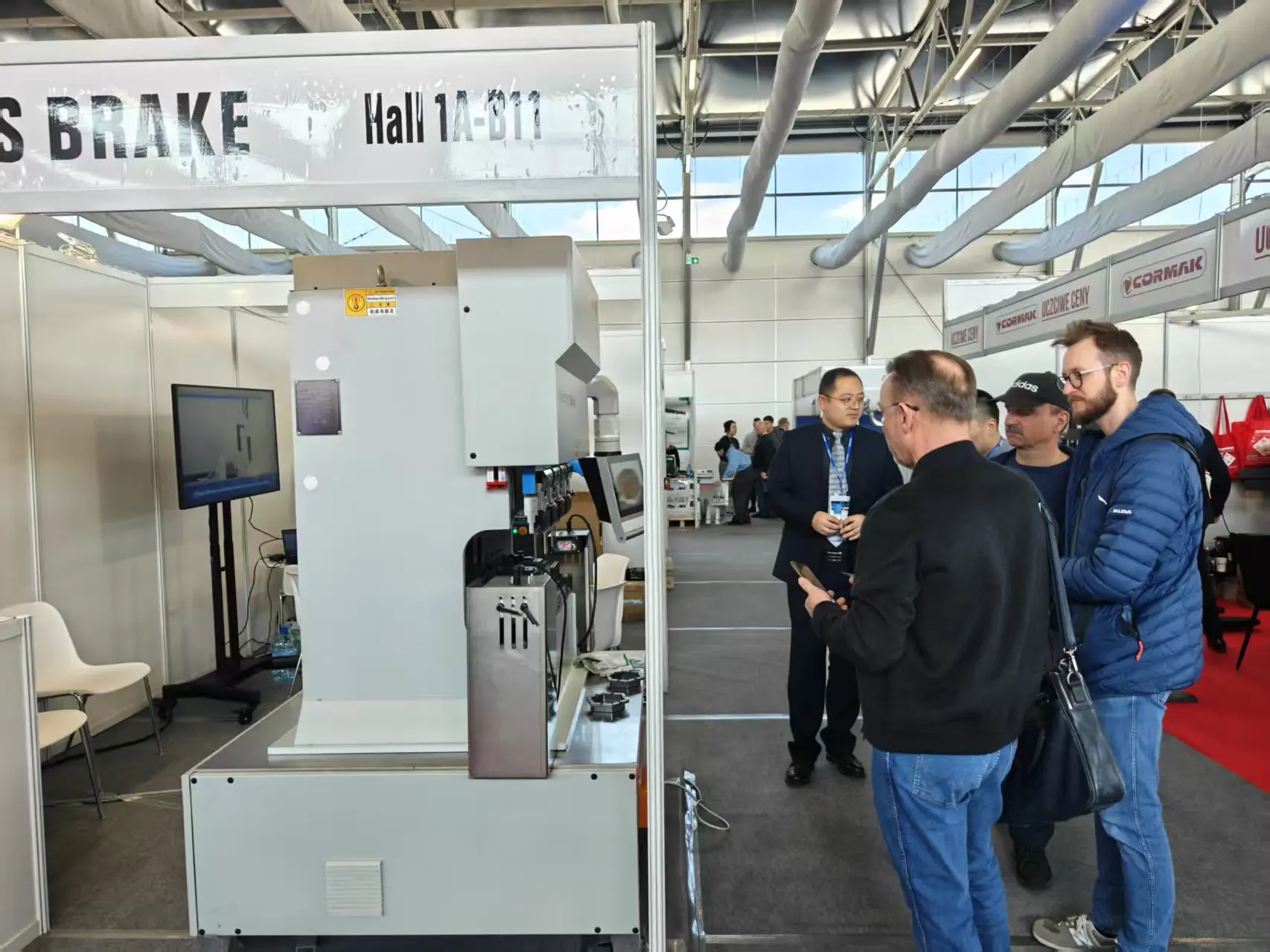

Press Brake

Press Brake CNC Laser

CNC Laser Industry Robot

Industry Robot Plate Rolling Machine

Plate Rolling Machine Tube Bending Machine

Tube Bending Machine Lathe and Machining Center

Lathe and Machining Center Machine Protection Products

Machine Protection Products