Inquiry

Form loading...

-

Phone

-

E-mail

-

Whatsapp

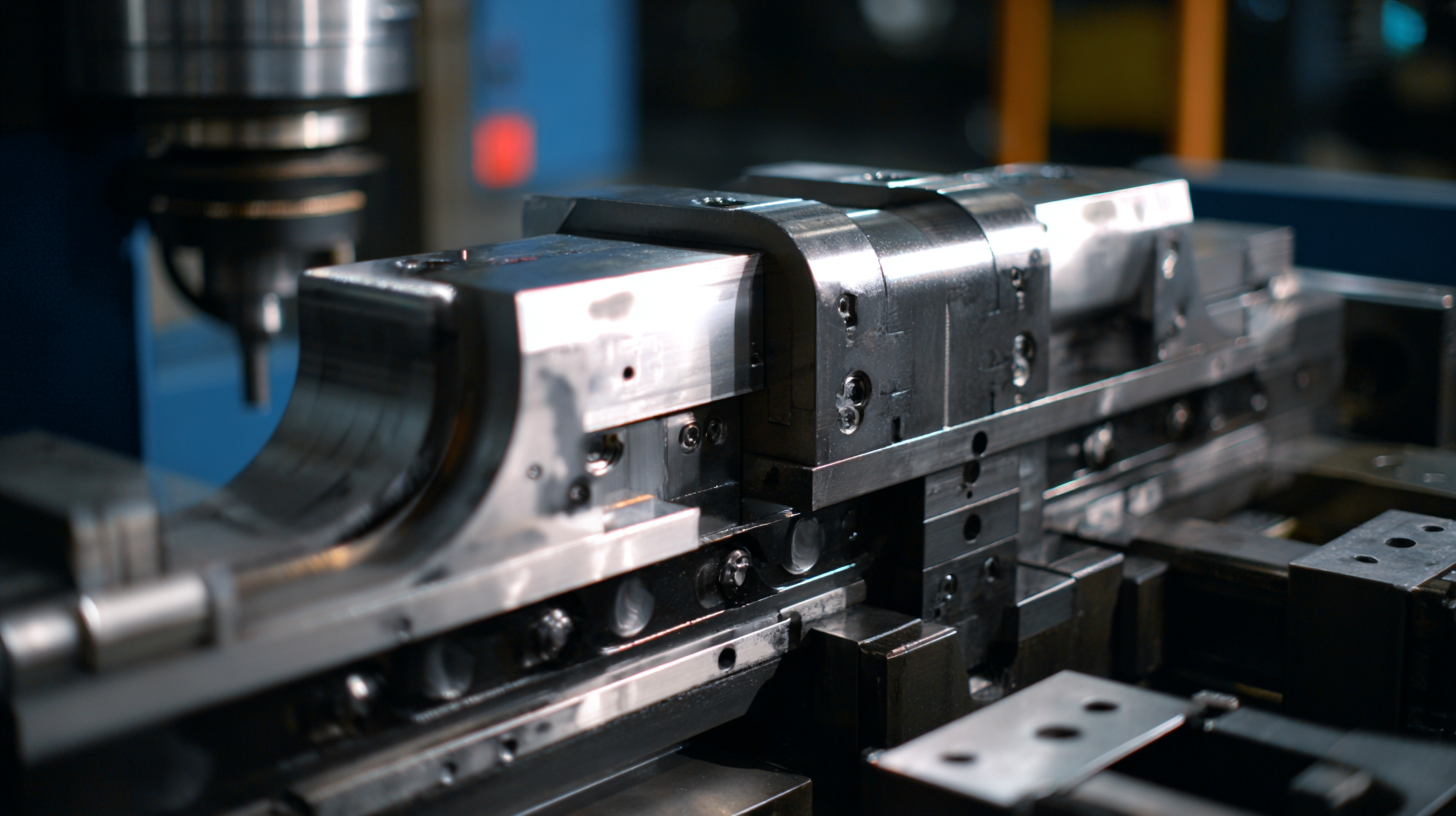

In recent years, the manufacturing industry has witnessed a remarkable transformation, significantly influenced by advancements in technology. One crucial development has been in the domain of Tube Bending Machines, which have evolved to meet the demands of modern production processes. These machines are not merely tools; they represent a convergence of precision engineering and innovative design that facilitates the efficient shaping and manipulation of tubes used in various industries.

The progression of Tube Bending Machines has enabled manufacturers to enhance their operational efficiency, reduce waste, and produce more complex designs with high accuracy. This evolution has been driven by the need for customization and flexibility in manufacturing, responding to the ever-changing market demands. Furthermore, the integration of automation and computer numerical control (CNC) technology has revolutionized the capabilities of these machines, allowing for faster production cycles and improved quality control.

In this article, we will explore how the evolution of Tube Bending Machines has shaped modern manufacturing practices. We will delve into the technological advancements that have contributed to their effectiveness, analyze their impact on production efficiency, and discuss future trends that may further enhance their role within the industry. Understanding the significance of Tube Bending Machines in contemporary manufacturing not only illuminates their importance but also highlights the broader implications for industrial innovation and growth.

The historical progression of tube bending technology has significantly shaped modern manufacturing processes. Initially, tube bending methods were rudimentary, relying heavily on manual labor and simple tools. Over the decades, the introduction of mechanical and hydraulic bending machines revolutionized the construction of complex geometries, enhancing efficiency and precision in production. According to industry reports, advanced tube bending machines can now achieve tolerances within 0.1 mm, a remarkable improvement from earlier methods that often resulted in variances that could exceed several millimeters.

The recent developments in cold-formed steel technology further emphasize the evolution of tube bending methods. For instance, the 2024 Summit on Cold-Formed Steel in Tianjin highlighted the importance of innovative applications within the structural steel industry. As the sector celebrates milestones like the 50th anniversary of key industry players, the focus on lightweight and durable materials continues to drive advancements. Reports indicate that the adoption of high-strength, lightweight materials not only optimizes material usage but also enhances the sustainability of construction projects, showcasing how far tube bending technology has come in meeting modern manufacturing demands.

Over the decades, tube bending machines have undergone significant innovations that have revolutionized manufacturing processes. In the 1960s, the introduction of hydraulic bending technology allowed for more precise bends with less effort, leading to increased efficiency in production. According to a 2021 market report by Research and Markets, the global tube bending machine market is projected to grow by 6.5% annually, reflecting the rising demand for custom pipework across various industries such as automotive and aerospace.

In the 1990s, the advent of CNC (computer numerical control) technology further transformed tube bending machines. CNC systems enabled manufacturers to create complex shapes and maintain rigorous tolerances at unprecedented speeds. This innovation not only enhanced productivity but also helped reduce material waste, as highlighted in a study by the Society of Manufacturing Engineers, which reported that CNC machines can minimize scrap rates by up to 30%.

Tip: To optimize your investment in tube bending technology, consider integrating CNC capabilities. This can significantly improve flexibility and allow for quicker adjustments in designs without extensive retooling. Additionally, staying updated on technological advancements can help businesses remain competitive in a rapidly evolving market.

The role of automation in modern tube bending processes has become increasingly critical as manufacturers aim to meet the demands of precision and efficiency in an evolving market. With the bending machine market projected to grow from USD 9.5 billion in 2024 to USD 16.6 billion by 2034, automation stands at the forefront of this transformation. Automated tube bending systems not only enhance the speed and accuracy of production but also incorporate smart technologies that align with Industry 4.0 principles. This integration allows for seamless communication between machines, enabling manufacturers to achieve error-free bends consistently while optimizing workflow.

In particular, the rise of fully automated tube bending cells is revolutionizing the way manufacturers approach their operations. These systems streamline processes from material handling to the final product, thus significantly reducing labor intensity and increasing safety. As industries such as automotive and construction evolve, the demand for high-quality, customized products necessitates advanced bending solutions. By investing in automation, companies can not only keep pace with market trends but also drive innovation, ensuring they remain competitive in a rapidly changing landscape.

| Year | Technology | Key Features | Impacts on Manufacturing | Automation Level |

|---|---|---|---|---|

| 1950s | Manual Bending Machines | Hand-operated, simple mechanical design | Limited production capabilities and high labor costs | 0% |

| 1970s | Hydraulic Bending Machines | Increased power, greater bending range | Improved efficiency and reduced labor costs | 20% |

| 1990s | CNC Tube Bending Machines | Computer-controlled precision with programmable settings | High accuracy and reduced waste, customized production | 50% |

| 2010s | Robotic Tube Bending Systems | Integration of robotics for automation and flexibility | Maximized productivity and minimized manual intervention | 80% |

| 2020s | Smart Tube Bending Machines | IoT connectivity, real-time monitoring | Data-driven decisions, predictive maintenance, and optimization | 95% |

The evolution of tube bending machines from traditional methods to CNC (Computer Numerical Control) technology has significantly transformed modern manufacturing processes. Traditional tube bending relied on manual techniques, requiring skilled labor to control the bending tool and ensure precision. This approach was often labor-intensive and resulted in variations in the final product, making it challenging to meet stringent industry standards. Operators needed extensive training, and even then, inconsistency in bends across different parts was a common issue that manufacturers faced.

In contrast, CNC tube bending machines leverage advanced technology to automate the bending process. With computer integration, these machines can execute complex bending patterns with high precision and repeatability, greatly reducing human error. Programmable parameters allow for adjustments on the fly, ensuring that manufacturers can produce intricate designs with tight tolerances. This shift not only enhances production efficiency but also opens up new possibilities for innovation in design and material use. As a result, CNC technology has become a staple in industries demanding high-quality, consistent components, underscoring a significant leap forward in manufacturing capabilities.

This chart compares the performance of traditional tube bending machines versus CNC tube bending machines in terms of production speed and setup time. CNC bending shows a significant advantage in both categories, demonstrating its impact on modern manufacturing efficiency.

The future of tube bending is poised for transformative changes as manufacturing processes evolve with technological advancements. Automation and smart technologies are increasingly integrated into tube bending machines, leading to enhanced efficiency and precision. As manufacturers look to reduce waste and optimize resources, automation plays a crucial role in driving productivity and ensuring consistent quality. Moreover, the integration of Industry 4.0 principles is paving the way for machines that can communicate with each other, enabling more responsive manufacturing systems.

Tips: When considering investments in tube bending technology, prioritize equipment that supports flexibility and ease of use. Machines that allow for quick adjustments and have user-friendly interfaces can significantly reduce setup times and improve throughput.

In addition to automation, there is a growing trend towards sustainable manufacturing practices in tube bending operations. Manufacturers are evaluating their material choices and implementing processes that minimize environmental impact. Innovations such as energy-efficient bending techniques and recycling waste materials are gaining traction. As sustainability becomes a top priority, businesses that adopt environmentally friendly practices may also see improved brand reputation and customer loyalty.

Tips: Keep an eye on emerging materials that are not only lightweight but also offer enhanced durability. Adopting these materials can contribute to sustainability goals while improving the performance of your products.